In the era of Industry 4.0 in iiot, the Internet of Industrial Connected Objects (IoT), cloud computing, or big data, it is essential to determine how information can help us make the best decisions or bring added value for the customer.

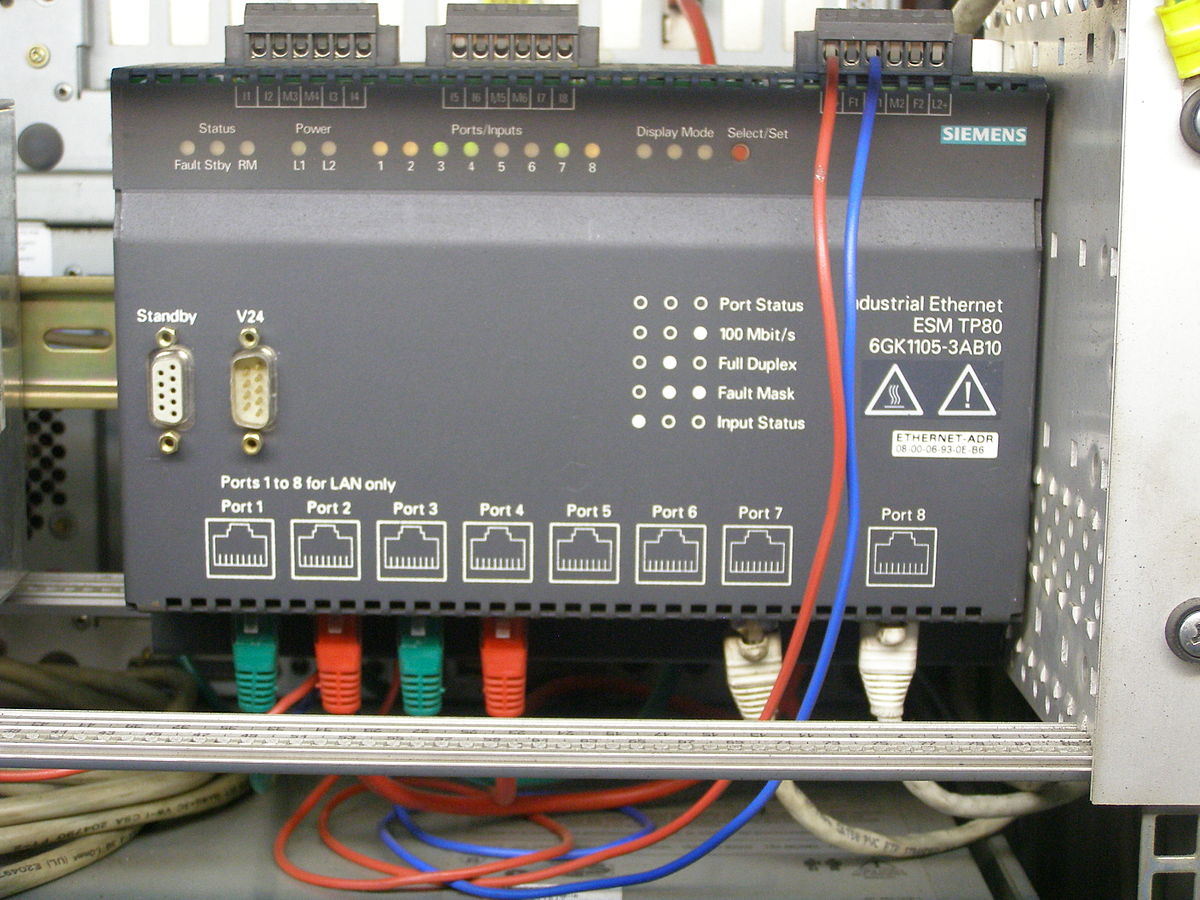

In particular, the implementations of factories of the future have seen the emergence of gateways, in particular Ethernet. They allow users to collect and structure data, analyze and filter it, and ensure connectivity and transport of this information to applications.

The Advantages Of An Ethernet Network

Connectivity is essential to access information. This requires the establishment of an industrial Ethernet network. Indeed, the data, which can be stored in a cloud, necessarily passes over the internet.

Choosing an Ethernet network brings many advantages. The main thing is that it is a standard protocol (ISO / IEC 8802-3) widely available on the market since it has been around for almost 45 years. So, it is now universal, and we can imagine that other networks may lose influence in the more or less near future. Industrial Ethernet has indeed surpassed traditional field buses in terms of new nodes installed in industrial automation systems.

This is the conclusion of the annual study “HMS Industrial Networks’ annual study “Concerning the industrial network’s market. Ethernet-based networks now account for 52% of new nodes installed (compared to 46% last year), while fieldbuses account for 42% (compared to 48% last year). The big winner being Ethernet / IP, which is now the most popular network.

Breakdown Of The Market Shares Of The Various Field Buses, Including Ethernet

Ethernet (green) in iiot technology is now predominant in the market. An additional advantage is that an Ethernet network is a simple protocol to implement. Transfer speeds are constantly increasing. There is a multitude of network topologies available for Ethernet. The addressing possibilities are much more comprehensive than on other standards. In addition, an Ethernet network is easy to diagnose because it is scanned globally. Thus, maintenance operations can be carried out more quickly than with other bus types on the market.

New Possibilities

If you’re still not convinced, then let’s talk about real-time capabilities. This technology allows real-time communication over Ethernet. This helps ensure the speed needed for the fastest applications.

It is for this reason that each station in the network has its internal clock. The clocks of all stations are synchronized. This ensures that each continuously follows the same communication cycle. They must also perform the actions within a given time interval and in a coordinated manner. This type of network can be used for the control command of handling systems. For example, different actuators must move in a coordinated manner: applying glue on a profile.

Modern network technologies like TSN (time-sensitive networking), are integrated into Ethernet and give the protocol new perspectives. Industrial Ethernet is, therefore, the appropriate technology for IoT and Industry 4.0. And it continues to be the favorite business platform. Examples of ideal applications are, for example, motion control, where system speed and performance are critical.

Ethernet makes sense in the Internet of Things because it makes it easy to connect industrial facilities and equipment. Most systems are compatible with Ethernet (motors, sensors, pneumatic terminals, etc.) and offer better performance. They represent the first stages of connected factories. Ethernet is not only beneficial for new designs,